Finishing Tool Concepts

These mechanisms inside the tools permit an important reduction in the initial investments, place occupation, directly employees and improves the quality of finished parts belonging to a established cycle. Incorporate systems like Finishing Tool Concept is a warranty of quality, efficiency and competitivity.

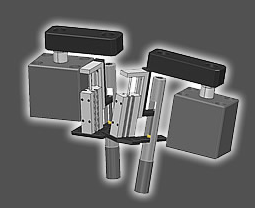

Finishing Tool Punching

This system consists in integrating one or more mechanisms inside the mold which permits the punching of wholes in the blow molding part in the same cycle. Once punched the scrap stays retained in the mechanism, after ejecting the part the scrap can be extracted mechanically from the punch. Due this system our client improve considerably the quality of his parts avoiding the drilling process which eventually produces internal trash leading to a refuse of the part.

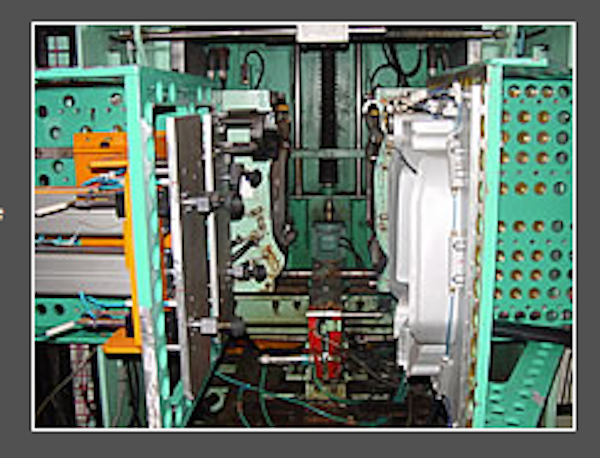

Finishing Tool Deflashing

If the client so requires, we can adapt to the mould a deflashing tool, which enables him to obtain completely finished parts in each cycle of the machine. These tools can also be independent of the blowmoulding machine. Due this system our client needs fewer place in its plant avoiding a peripheral machine to do this process or permits its employee using the time mounting or packaging instead of deflashing the part manually

Finishing Tool Cutting

This system consists integrating a mechanism inside the mould which allows the cut of domes during the blow cycle process. The cut of domes can be made partial, leaving a little union with the part in order to allow the machine claws actuate extracting the part from the mould or a 100% cut separating totally the dome from the part. The election to one or the other version depends on the needs our clients.